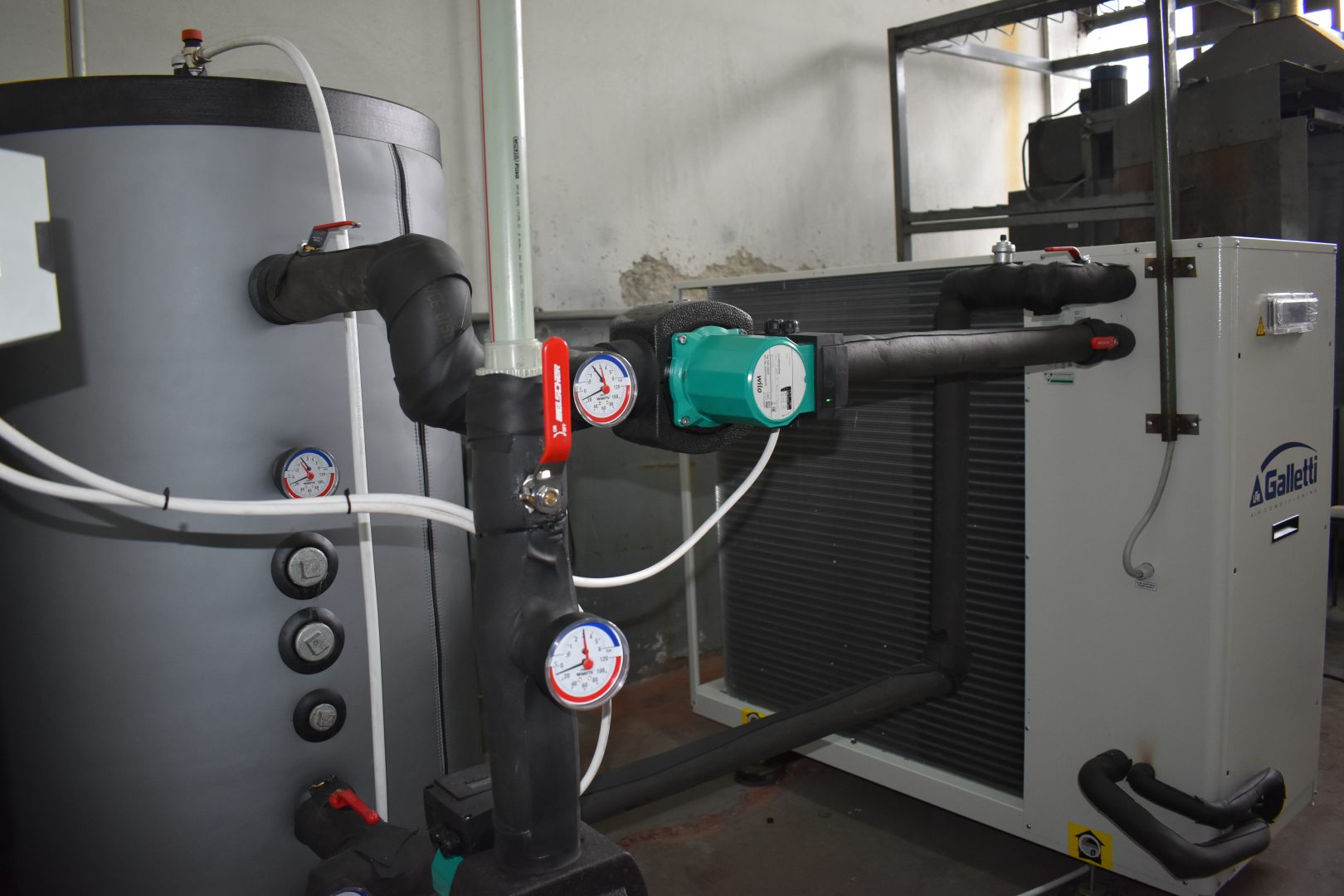

We are happy to announce that on the World’s Water Day, March 22nd we have started with the implementation of the closed-circuit cooling system with water-to-air chiller in our production process. By doing so, we are now using up to 10 times less water than before i.e. have significantly reduced our water waste footprint.

The addition of this equipment in our plastic parts production process supports both our corporate environmental sustainability goal as well as the company’s continuous processes improvement.

By using it, we are moving away from our open well-water-cooling system to closed water-cooling system.

This operation has been conducted in coordination of our two departments, the Department of Technology Development and the Department for Mechanical and Electrical Maintenance.

This might be a small step for the human kind, but it is a big step for our footprint reduction!